Florida State Home Inspectors Thermal Imaging Inspections Services

Infrared inspection (thermography) can be defined as the detection and measurement of emitted thermal energy (heat). This is enabled by the use of an infrared camera which translates the invisible infrared spectrum into a visual format, or thermal image. This thermal image can then be interpreted to provide a noninvasive and nondestructive method of identifying building defects and deficiencies. In addition to finding problems, infrared inspections are useful for clearance purposes and also to confirm that previously determined issues have been properly corrected or remediated.

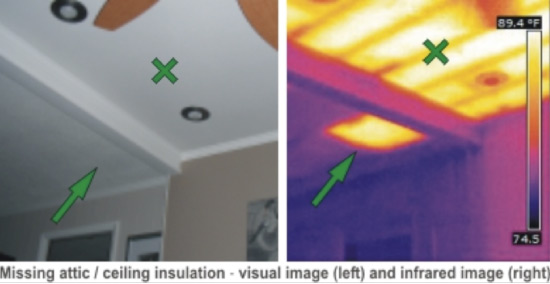

Sample infrared image: below are sample images of the same area (visual image at left and thermal image at right). Nothing is apparent when looking at the visual image, but missing insulation is very apparent in the thermal image. Lighter colors represent progressively warmer temperatures (areas of missing insulation), while darker colors represent progressively cooler temperatures.

Examples of Infrared Inspection Applications

Water intrusion: our thermal imaging services include scanning interior surfaces of a building with an infrared camera can reveal excess moisture due to plumbing leaks, roof leaks, leaks around windows, etc. Wet areas of building materials cool when energy is transferred during the water evaporation process; therefore, a wet (“cooler”) area will stand out from the surrounding dry (“warmer”) surface.

Insulation deficiencies: appreciable temperature differences, due to variations in thermal energy (heat) transfer, allow for detection of deficient or missing insulation when scanning ceiling and wall surfaces.

Roofing leaks: scanning roof coverings can reveal water intrusion and accumulated moisture below the surface. Due to its thermal properties (high thermal capacity), water typically gives up heat at a much slower rate than the surrounding roof materials. The areas of accumulated moisture can therefore be detected when scanning the roof surface. This type of roof inspection is best done in the evening or early nighttime after thermal energy imparted during the daytime is transferred or released.

Electrical systems: deficiencies within the electrical system can be made visually apparent by use of an infrared camera. For example, a deficient connection between electrical components can result in resistance which will manifest in an apparent temperature elevation when compared with similar types of connections under similar load conditions.

Structural issues: differences in thermal capacity, conductivity, and other intrinsic qualities of building structural components can allow for their detection when scanning walls, floors, and ceilings with an infrared camera. Under the right conditions, missing structural components, and portions of structural components which are damaged (to the extent that their intrinsic qualities are significantly changed), can be detected.